Vui lòng nhập lại email đăng ký,

chúng tôi sẽ gửi cho bạn một liên kết để thay đổi mật khẩu.

| Brand Name: | OSSIEAO |

|---|---|

| Origin: | CN(Origin) |

| Output Power: | MAX 75W |

| Dimensions: | Null |

| Input Voltagle: | DC 12-24V |

| Output Temperature: | 200C-450C |

| Temperature Stability: | plus or minus 10C |

| Certification: | NONE |

| Model Number: | T12 |

| Acquiescence Soldering Tip: | T12-k Soldering Tip shape(you can change to other tip like our photo) |

| LED Color Optional: | Blue,red,green,white,you can choose the color you want! |

| Input voltage: | 12V-24V |

| Temperature adjustment range: | 200C-450C |

| T2 / T12 handle (907 handle conversion): | Applies to T2 / T12 Series Tip, default is black color. |

| Feature: | include the solder and flux |

| 2017 new version: | 1. Temperature recalibration error control at 15 ℃ 2. Compatible with |

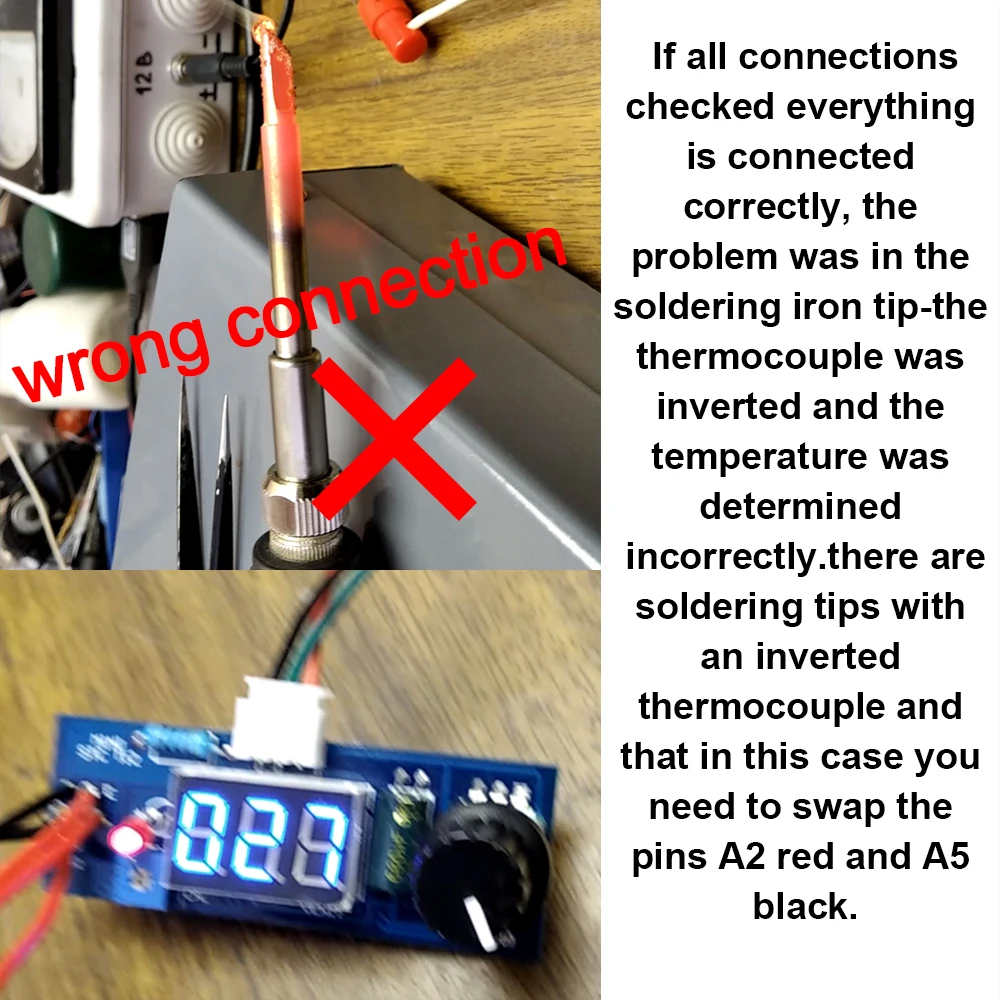

| if temperature value of dozens jumping: | see our manual Step 5 |

| Package listing: | 1xAs the main photo shows all diy kit |

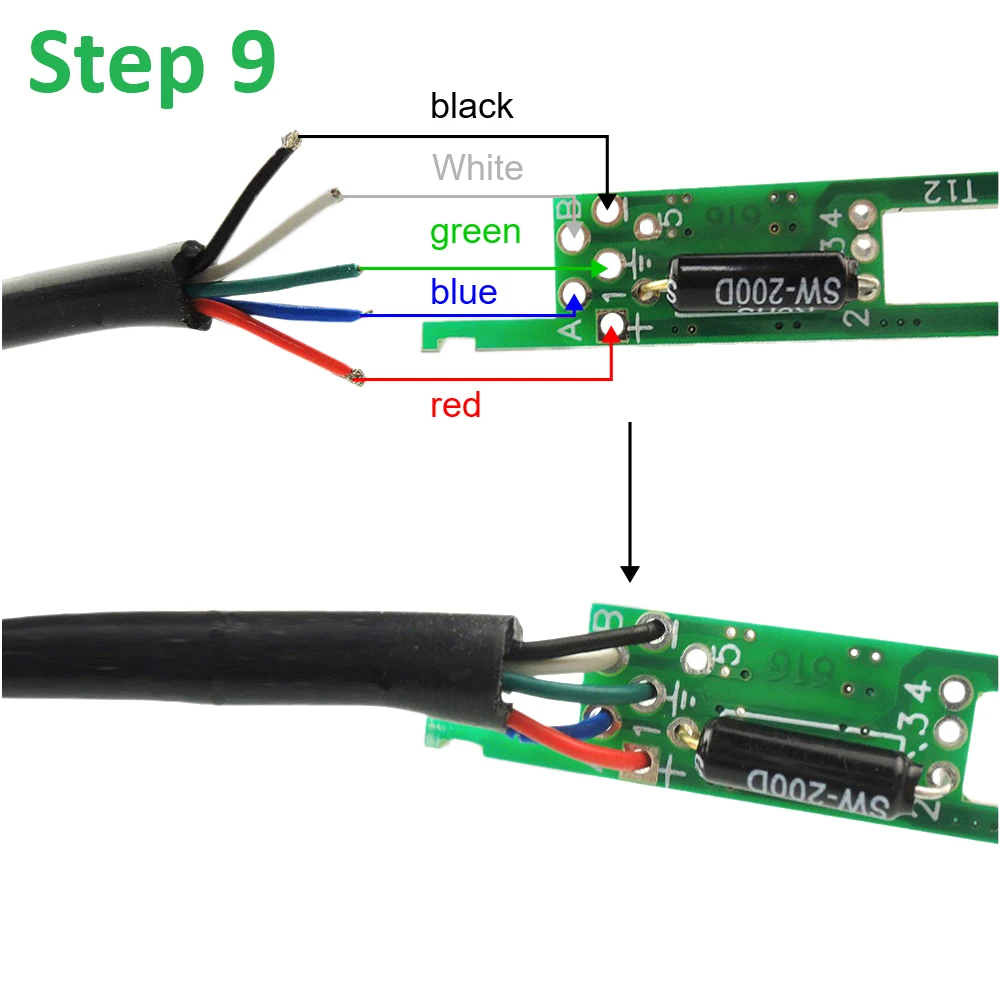

| If when insert T12 tip ,it burn and hot: | please check our manual,make Vibration switch the right connect |

| Note: | The DIY kits not include the shell or power supply! |

| display show 500,not heat up: | check again the handle and vibration switch |

| when soldering the handle: | like our manual,can not touch each other |

| note2: | the heater handle, needed to be screwed to the end. |

New arrival!

Click into the following photo to have a see!

Please read the description before order!

Just choose the 4 color you want,it will be The DIY Kits like the main photo!This product

not include the ABS shell or power supply !You can order that in addition!

The kit is a DIY product, T12 tip will be different from the random purchase, T12 tip can be used for HAKKO T12 handle, quality assurance, customers can rest assured to buy. We are the DIY kits, not kits produced by HAKKO.

Question:if display show 500,T12 tip not heat up,hope you can check again the handle and vibration switch like our manual or video,because if the T12 tip not insert or the handle wrong connect,it will show 500!

pay attention:when soldering the handle or others like our manual,can not touch each other

Question: the temperature does not correspond to reality, the display is 200 ° with and in fact the temperature of the tip is 300 ° sec. Why is that?

Answer :see the following,change P03 and P07

The Package listing as the main photo shows all diy kit(But If you choose

ABS shell

or

24V4.5A power supply switching transformer

,the package only the part you choice not the DIY kits!)

We suggest not order the

Shell

together with

the following24V 4A 6A power supply switching transformer(we don't sell this power supply now)

,because it need you to change the shell to have enought place for Power supply,you can do like the following photo as my other Customers do!

(you can choose our new 4.5A power supply)

This

And this

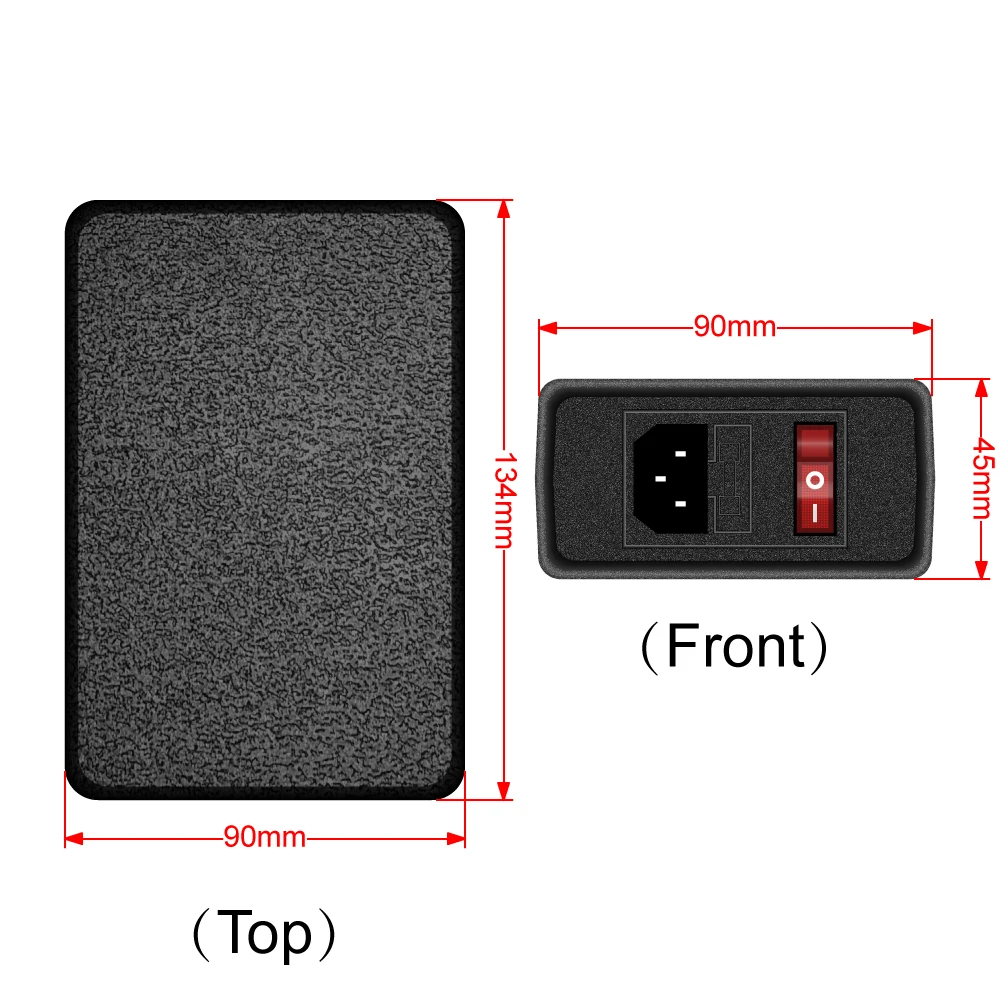

The size of ABS Shell and this power supply you choice like the following photo

our new 24V 4.5A power supply suitable for the shell ,you can order that in this link in addition!

Problem of power:

If the product is no other use of the problem, the value of several degrees - dozens of degrees of temperature jumping are generally power problems, our manufacture use used genuine Apple power,the proposed use of good quality brand manufacturers of genuine power like Taiwan genuine Mean Well power or Apple power!

This product not include power supply,

suggest that you try to use the T12 Power supply requirement like the photo i upload andrecommended to try to use the power 19V-24V laptop switching power supply, printer supply or storage battery!

Note!!!English manual at the following bottom!

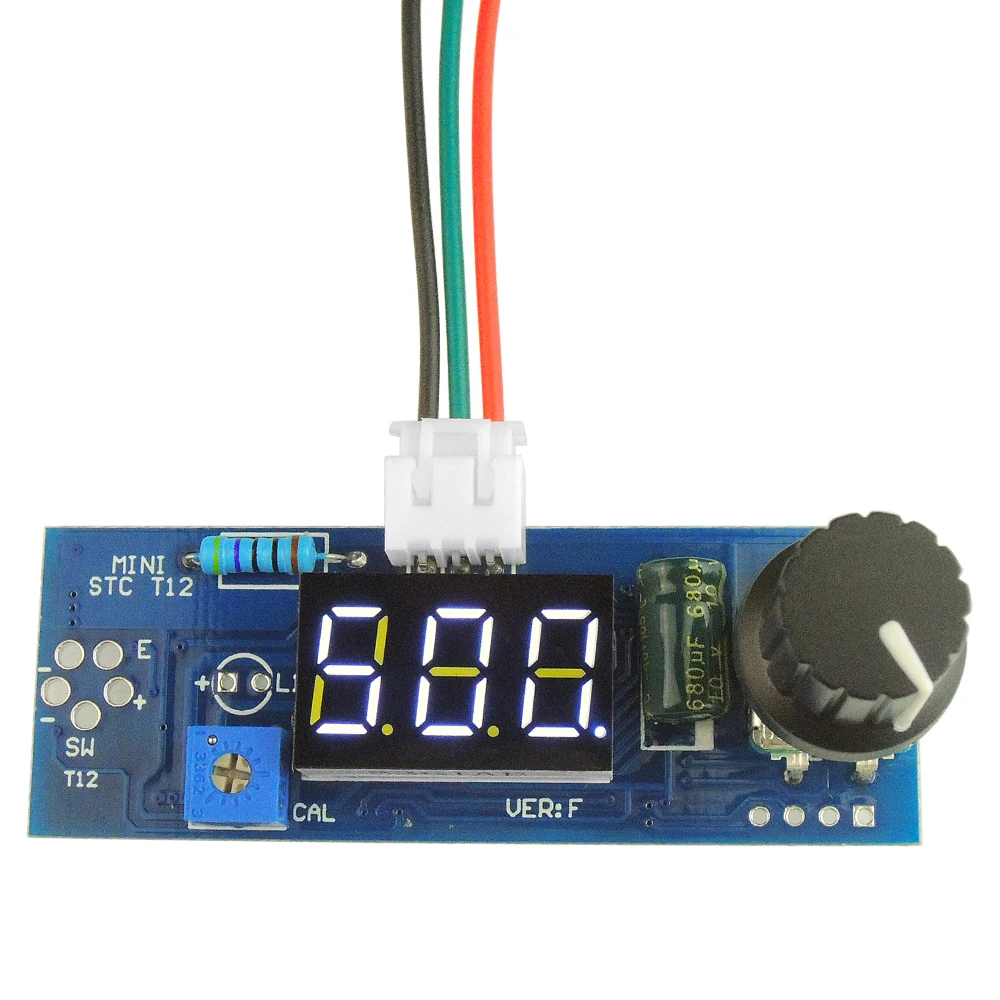

Dear friend,this product is 2017 new version,the new arrival soldering board is Version F or G!

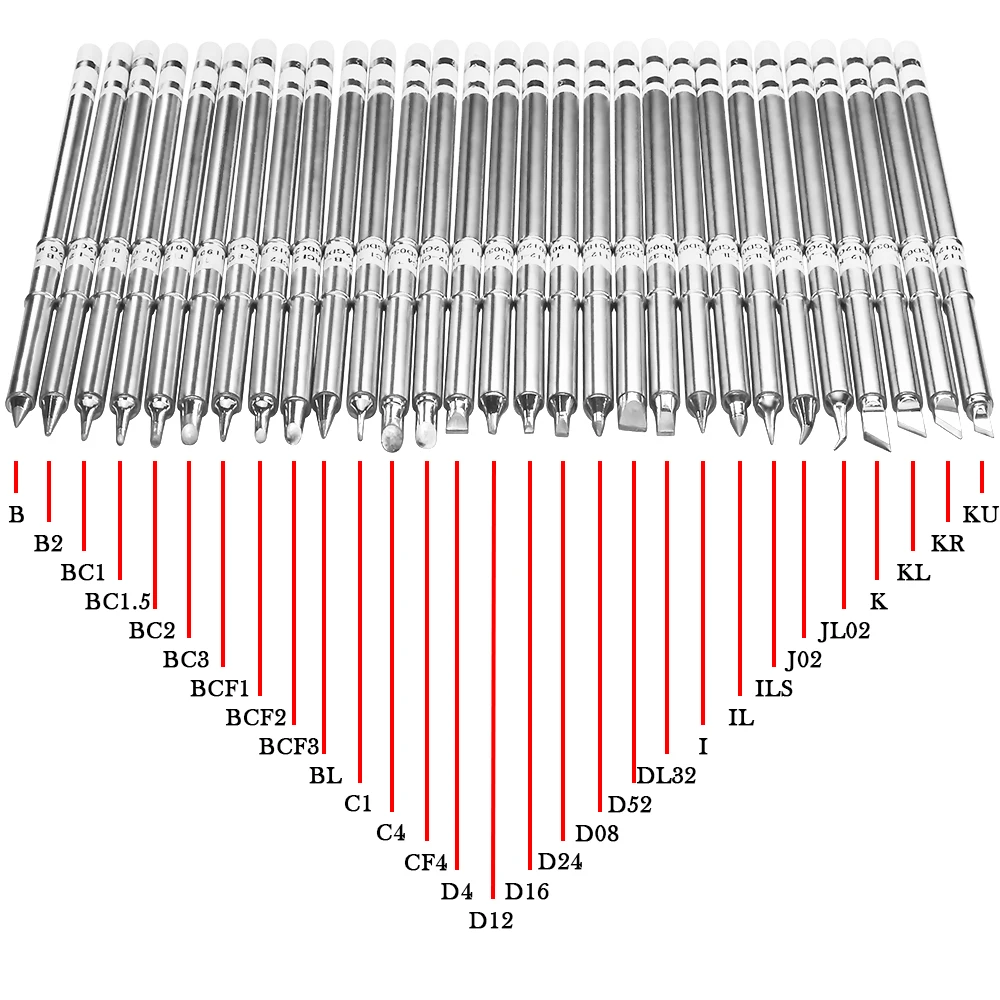

We will send T12 Soldering Tip T12-K

and if you want other tip in the following photo,you can left the message for me!

We will send that for you(instead of the T12-K tip)!

If you want more extratips,you can Click into the following photo(or the link),2pcs,3pcs,4pcs,5pcs,6pcs,7pcs,8pcs,10pcs/set,

15pcs/set,20pcs/setin sell,you can choose the tip you want in the picture!

New arrival discount wholesale tip:

5pcs/lot

,click into the photo and place the order,we will send the package you choose,

or you can place the order and left message for me the tips you want(the tips in the above picture) !

Attention:Before the test machine, be sure to confirm the correct line, positive and negative, otherwise the heating core must be heated to red and burn!

(

Detailed English manual is at the bottom!)

2017 New version(4 color optional

Blue,

Green,

Red,

White

)

This product not inclue the shell and power supply, if you want the alloy shell or our new 24v 4a power supply(it match the shell,not the 24v 4a 6a power supply ),you can choice that in addition or click into the following photo and place a new order!

This product is a DIY Kits, buyers need to own welding. DIY risk, novice buy carefully, If it is man-made damage, we do not assume responsibility, Thank you for understanding.

And the LED have 3 color: Blue,red,green,you can choice the color you want!

This item can use in T12 T2 T13 T15 heating core. auto sleep, ball bearing vibration. Blue light white word.

Diy Kits Descriptions:

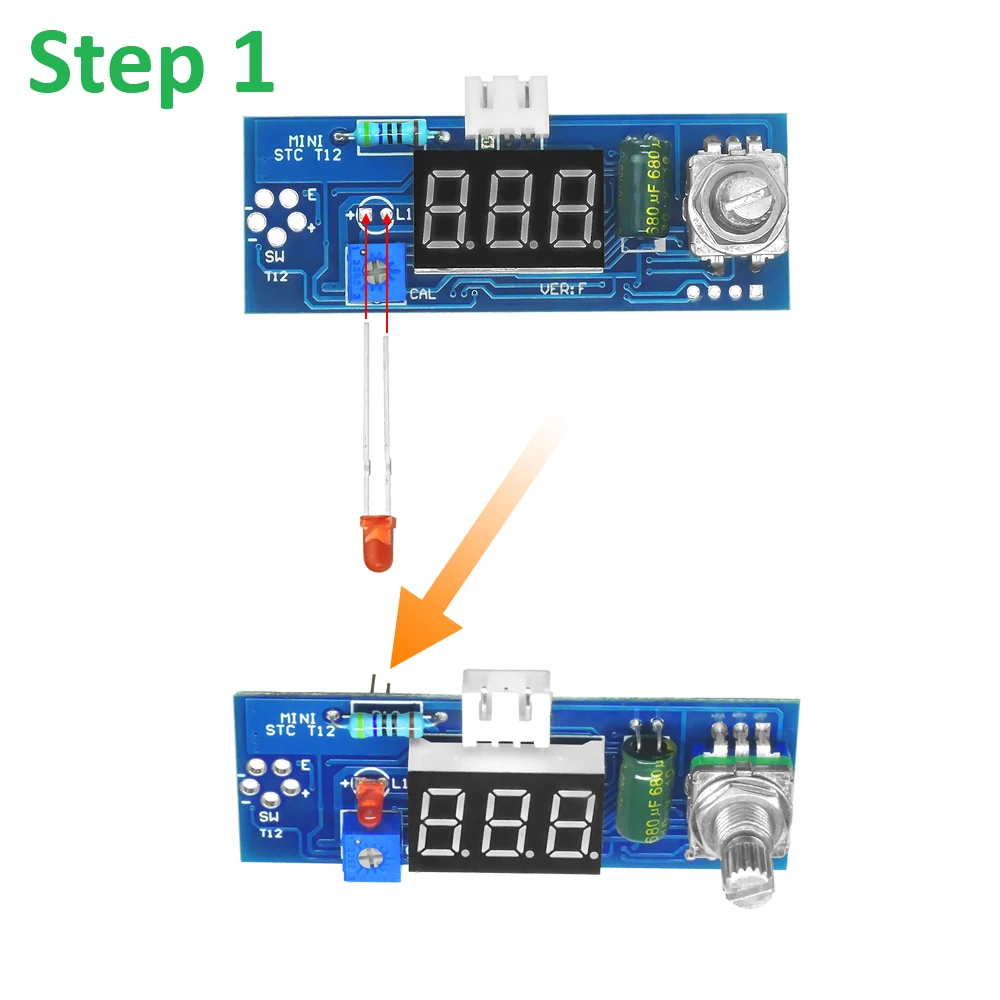

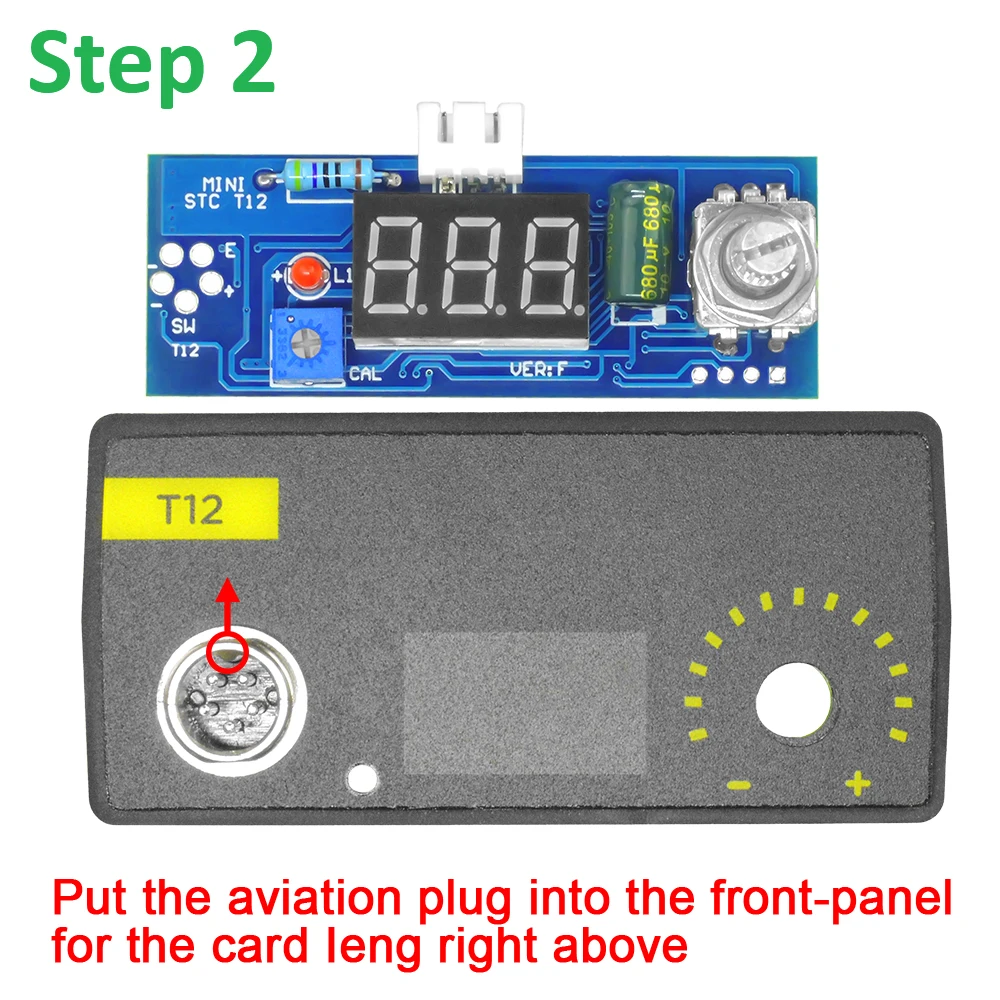

1. T12 digital temperature controller (vibration switch + LED + knob)

Input voltage: 12V-24V

Temperature adjustment range: 200C-450C Maximum Power: 75W

2.

T12 Soldering Tip shape-k

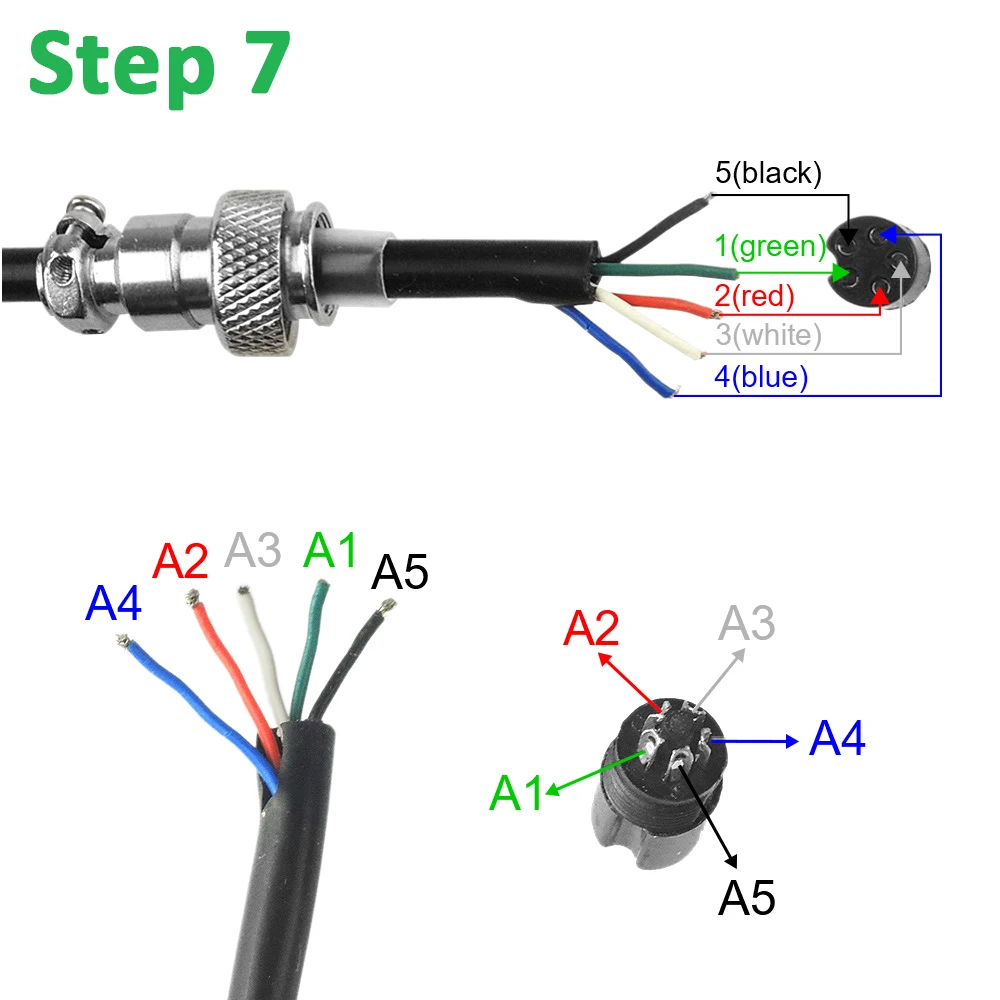

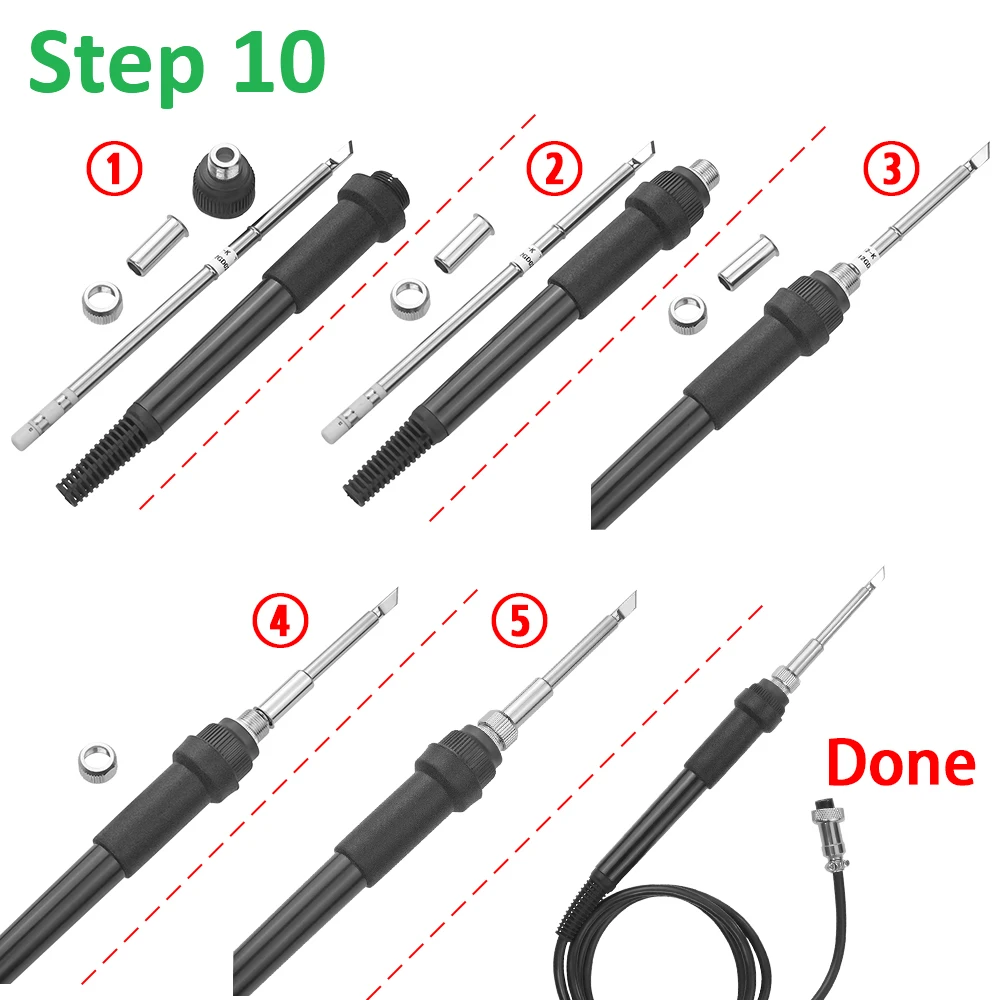

3. T2 / T12 handle (907 handle conversion)

4. T2 / T12 inner tube bracket kits

5. silicone 5 Core cable ,cable length: 100~110cm

6. Soldering station iron 5 core aviation plug

7.flux

8.the solder

9.Other cable/accessories (as picture shows)

Question: the temperature does not correspond to reality, the display is 200 ° with and in fact the temperature of the tip is 300 ° sec. Why is that?

Answer :see the following,change P03 and P07

Controller parameter setting mode:

(The default has been set, no special requirements, please do not set up a random)

Press and hold the encoder button does not move → start → enter the parameter settings mode:

There are 12 menus available for setup,P00,P01,P02,P03,P04,P05,P06,P07,P08,P09,P10,P11.The digital display menu is 1.5 seconds,and then automatically displays the corresponding parameters of this menu,at the same time rotate left encoder is reduced,right is increase,Press it and automatically save the currently set parameters.And then display the next menu for 1.5 seconds, and then display the corresponding parameters of this menu, and so on. When all parameters are set to automatically enter the normal heating mode.

Because each set a parameter to save once, so you can shut down at any time without having to set all the parameters (such as you just want to set P01, set P01 after you can shut down and then boot into normal mode)

Menu item:

P00: restore the default parameters (0 or 1, the default value of 0,0 for not recovering, 1 for the recovery)

P01: Operational amplifier gain (200 to 350 times, step 1, default 230)

P02: Operational amplifier offset voltage (0 ~ 250mV, step 2, the default value of 100, refers to the tip to keep the room temperature operational amplifier inherent output voltage, according to my measurement this voltage varies greatly with temperature, different magnification Not the same, the higher the magnification, if you do not measure, please keep the default value)

P03: thermocouple ℃ / mV data (30 ~ 50, step 1, the default value of 41, refers to the thermocouple need to temperature how much voltage was increased by 1mV, according to the type of thermocouple self-calculation, if you do not understand, please keep Defaults)

P04: temperature adjustment step (0,1,2,5,10 degrees optional, 0 can lock the soldering iron temperature)

P05: sleep time (how long don’t not move into sleep) (0 ~ 60 minutes, step 1, 0 is to forbidden the sleep function)

P06: Shutdown time (0 ~ 180 minutes, 0 ~ 30 step 1,30 ~ 180 step 10, 0 is forbidden shutdown function)

P07: temperature correction (+20 degrees, step 1) (due to NTC resistance in the chassis, the soldering station heat will lead to the detection of NTC temperature higher than room temperature, resulting in high temperature compensation of the thermocouple, soldering iron temperature is not accurate,or other causes the temperature is not accurate.If you set the other parameters are correct value but the temperature is still high or low, you can use this parameter correction.For example, to detect the displayed soldering iron temperature is 20 degrees higher than the actual value of this parameter Set to 20)

P08: wake mode (0,1, 0 in the shutdown mode can be rotated the encoder and also can shake the handle to wake up, 1 can only rotate the encoder wake up (Note: press the encoder can not wake up, can only rotate) )

P09: temperature increase mode to increase the temperature to adjustable (20 degrees to 100 degrees adjustable, adjust the pace of 10 degrees)

P10: temperature to increase the duration to adjustable (adjustment range of 10 seconds to 250 seconds, adjust the step 5 seconds)

P11: Parameter setting mode Auto save parameter and return to heating mode Function to active time adjustable (range 4 seconds to 60 seconds)

Installed Note:

1. Strictly reference shop tutorials, well insulated and grounded against static electricity.

2. Before power test, carefully check the wiring is correct, whether Weld and short, full power test machine after confirmation.

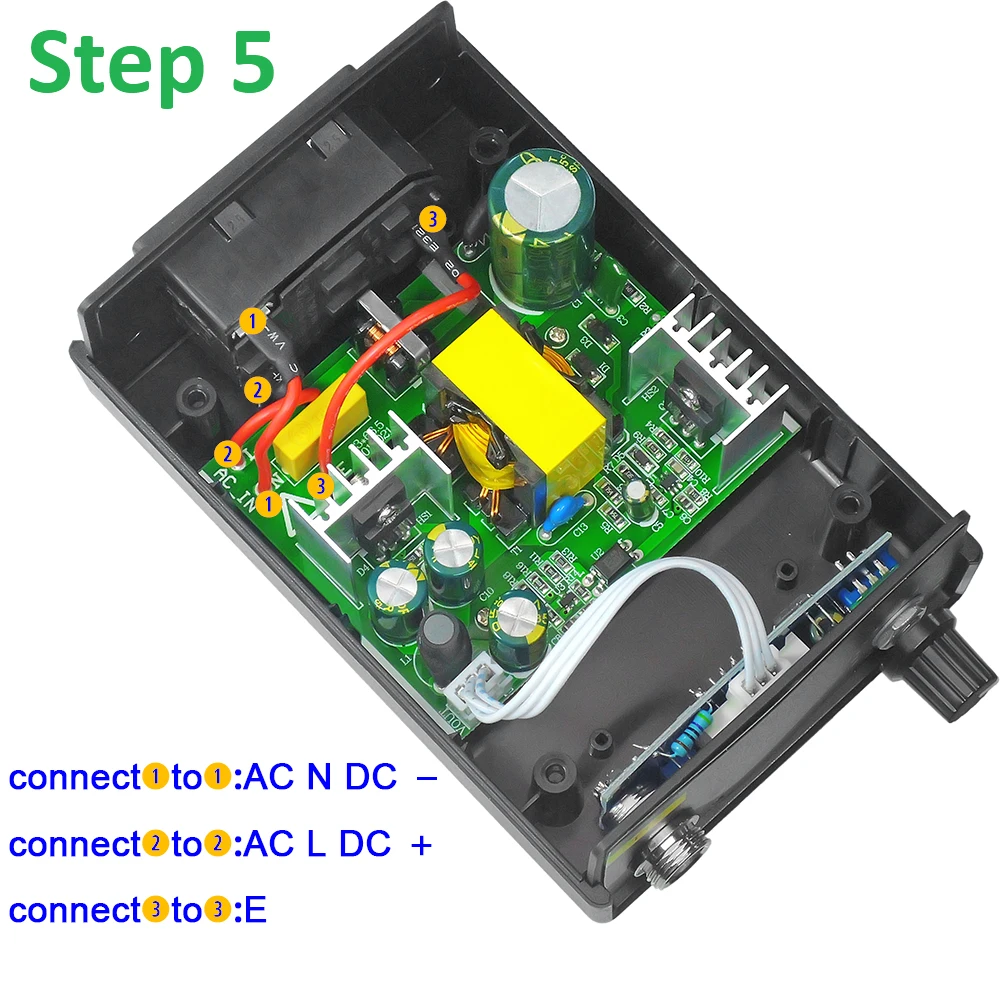

3. connect 12-24V DC, if received more than 20V power supply,2017 new style product don't need to remove anything!

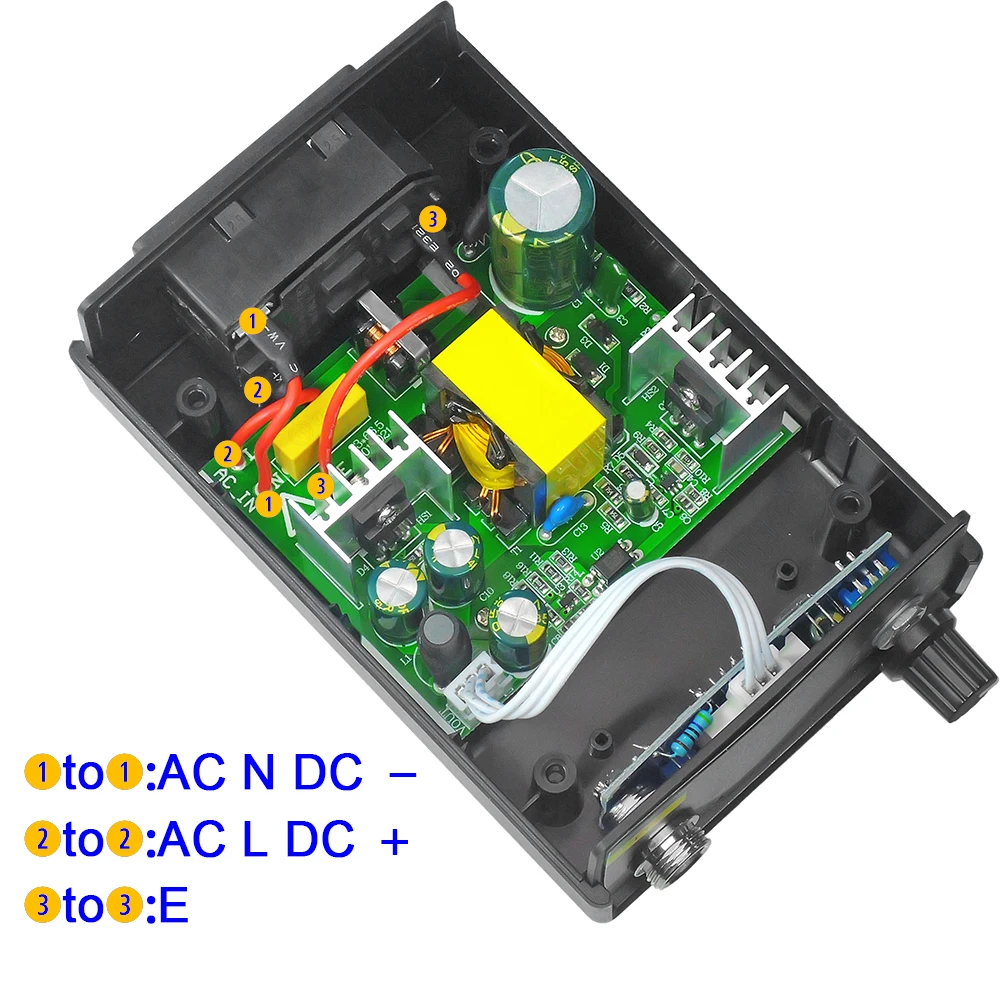

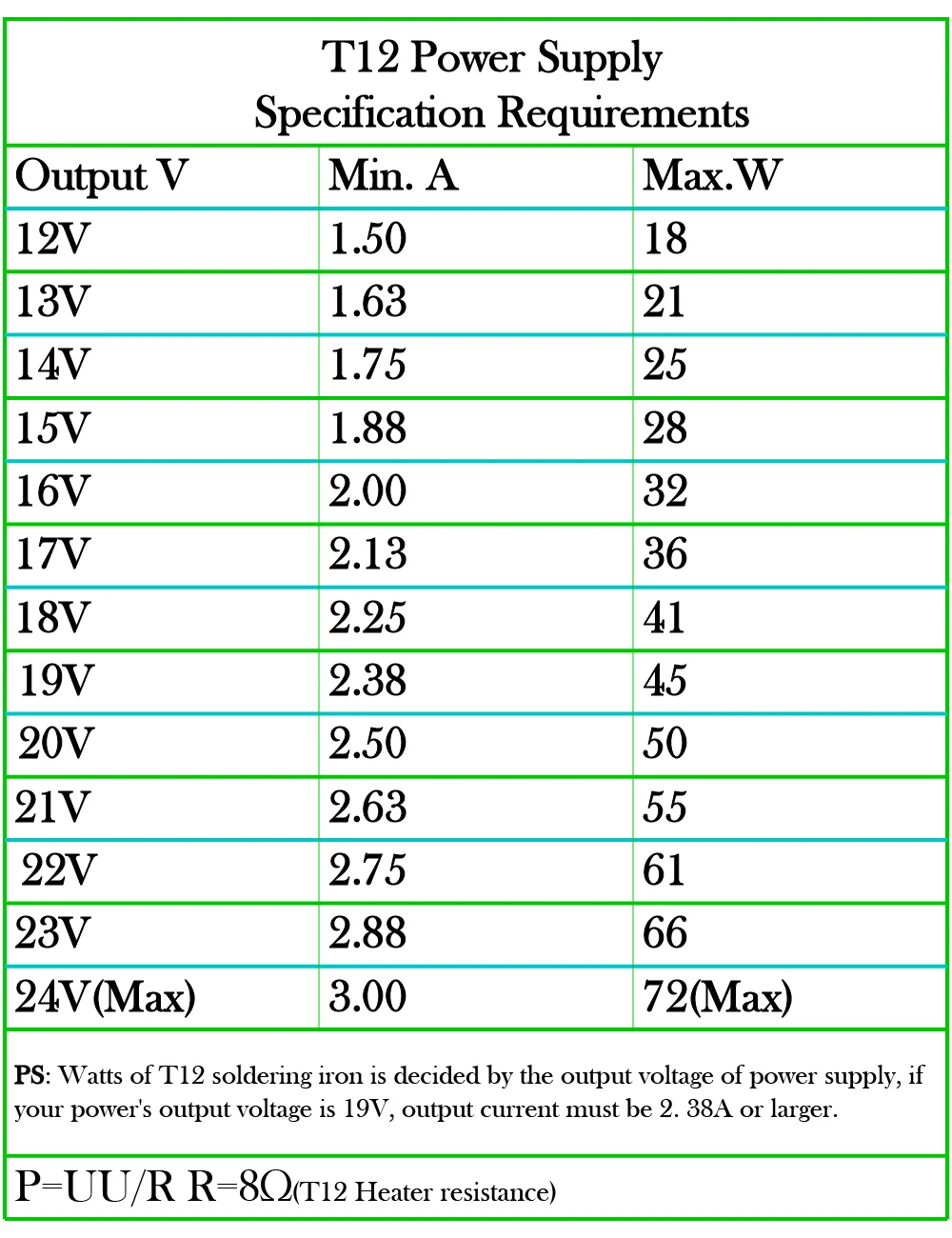

4. When you configure the power supply voltage and current requirements themselves refer to the following table:

Power (third column) is determined by the voltage (first column), as long as the current reaches the minimum current (second column).

Measuring Machine normal, lights and display status:

1. Unplugged T12 tip, turn the light flashed off, show SER, 1 seconds after the display 500.

2. T12 plug tip, boot light uniform flashing, indicating rapid heating from room temperature generally show the set temperature to rise, approaching the set temperature, strobe lights. Indicator is not flashing or intermittent flashes, indicating that the tip temperature reaches the set temperature or alternating temperature compensation.

When measuring machines on display digital bounce questions:

Because with the new T12 tip, the tip inside the heater did not burnt, it will be just a little jump start with warm, generally do not need special treatment, the natural use of 1-2 days basically not bounce up. If you need effective immediately, the general recommendations of the temperature to 350 -380 degree while heating to the point of tin iron head, burning off after 4-5 minutes, until the tip to cool before you can reboot! (1 no action can be repeated 2-3 times

)

More than 400 degrees, the temperature shows instability, it is the industry can not solve the whole, we commonly used temperature is 300 to 380 degrees, the basic use of less than 400 degrees, more than 400 degrees use, will affect the working life of the head

1x As the main picture shows all diy kit

English manual

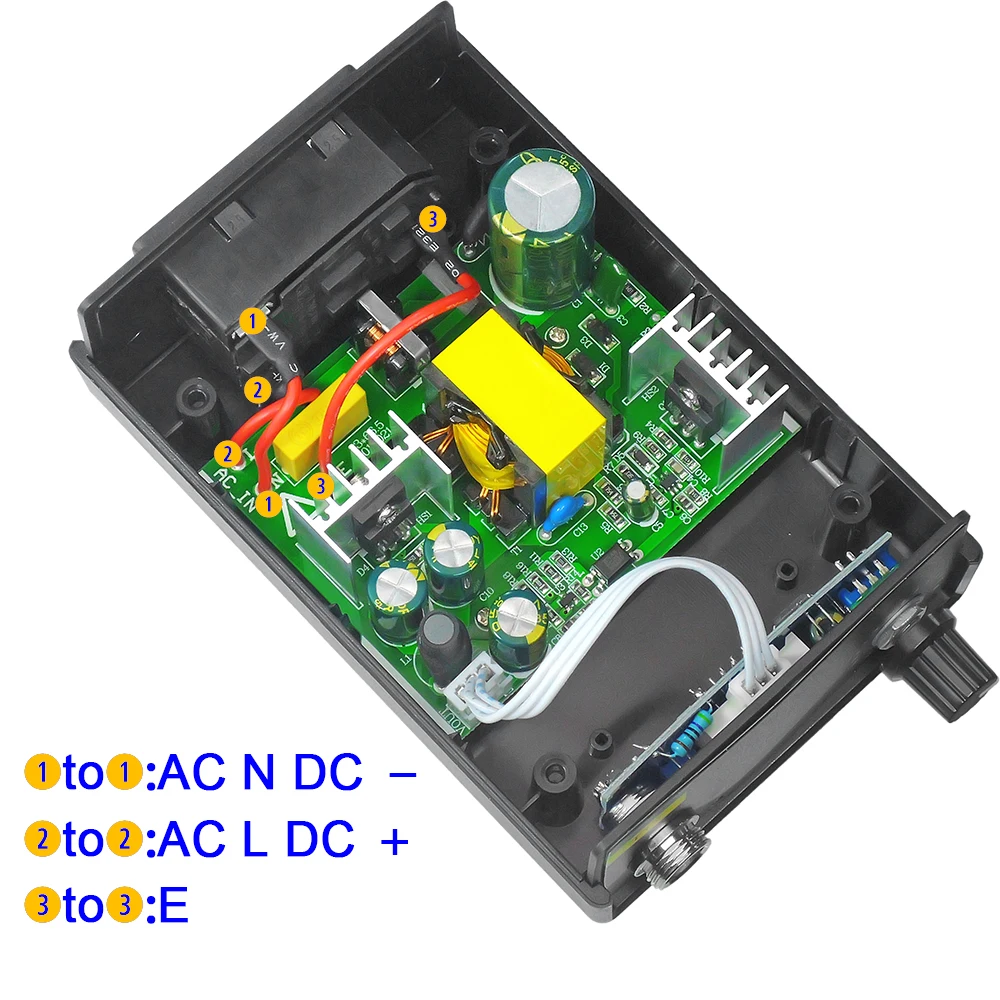

If you choose our new powr supply(the size suitable for our shell),the power supply connect like the following photo(click into the photo to choose the power supply if you like it)

(Note:this product

not inclue the shell and the power supply

,you can choose the ABS

shell

if you want in this link)

FAQ:

1. Why the temperature of the new T12/TS solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 ℃ -400 ℃, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12/TS first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12/TS tip?

a. If can use low temperature, then do not high temperature: T12/TS is constant temperature control, the general recommended working temperature control between 300 ℃ ~ 380 ℃, higher than 380 ℃ damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12/TS!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.

4.How to do when T12/TS tip does not absorb tin?

T12 iron head does not absorb tin, generally there are two reasons:

A. The head of solder tip is severe oxidation can not absorb tin.

B. Temperature can not rise up then can not tin.

C. The head is oxidized and can not the tin, you can use the soldering iron to clean the ball gently, then use the wet sponge rub and then heat the tin.

D. serious oxidation of tin, you can use more than 900 mesh sandpaper gently rub, with a small wooden board,

in the board to dig a small hole, put the rosin and tin in the hole, put the head of solder tip insert the hole, while heating and putting the tin,If you can prepare a tin stove, use scaling powder into tin stove put the tin to repair!

E. If T12 temperature can not rise up, the multimeter transferred to 20Omega stalls, test T12 solder tip positive and negative ring resistance. 8-10Omega belongs to the normal range, the factory standard is 8.4Omega, after using the resistance will be slightly changed!

Payment

1. 100% payment before delivery, please make sure you have make out the complete correct information, include full name, detail address, post code, phone number, the goods will be shipped to the address that you left in the order, and ldquoP.O. boxrdquo is not allowed in the address.

2. We prefer payment through ESCROW which is a security way for you. If you want to pay by other ways, please contact us.

3. When you place an order, please choose a shipping method and pay for the order including the shipping fee (except for free shipping).

Shipping

1. We will send the items within 1-7 days once your payment is completed.

2. We only ship to confirmed order addresses. Your order address MUST MATCH your Shipping address.

3. The images shown are not the actual item and just are for your reference.

4. SERVICE TRANST TIME is provided by the carrier and excludes weekends and holidays. Transit times may vary, particularly during the holiday season.

Feedback

1. Our goal is 100% positive feedback and 100% customer satisfaction. We do our best to serve our customers the best that we can. Your satisfaction and positive feedback is very important to us.

2. If you are not satisfied with the items you ordered, please contact us before leaving negative feedback. We can work together to resolve any dispute.

3. Please leave positive feedback and 5 stars if you are satisfied with our goods and services.

DELIVERY ESTIMATE

We processes orders between Monday and Friday. Orders will be processed within 5 business days of ordering and shipped the next day after the processing day. Please note that we don't ship on weekends.

We deliver your orders in 15-20 working days (free shipping), International orders delivery is subjected to the policy of third party courier service, and differs from country to country basis.

Due to the Covid-19 pandemic, you may experience delivery delays but we are committed to getting your order to you as soon as possible.

Note: Please ensure all delivery information is correct. If there is incorrect and/or missing information, we may be required to contact you to update the delivery information, which may cause delays in delivering your order. Delays may also occur as a result of customs clearance.

RETURN POLICY

At MMO-Dropship we strive to make our customers 100% satisfied with the product they’ve purchased from us. If you are experiencing any shipping or products issues, and you’re feeling frustrated, then please send us an email and our team will assist you right away.

We have a 7-day return policy, which means you have 7 days after receiving your item to request a return.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at [email protected]. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

You can always contact us for any return question at [email protected].

DAMAGED ITEM AND LOW QUALITY

For the fastest resolution, please include a photograph demonstrating the poor quality or the damaged area of the item. The most optimal pictures are on a flat surface, with the tag and error clearly displayed.

We will use this information to help you with your order, and eliminate errors in future.

REFUND POLICY

If you feel the product that you’ve purchased does not show the requirements that you initially had in mind, then you do have the option to request a refund.

Here are the circumstances in which refunds will be granted:

You can get a refund if:

Please note that refunds can take 3-5 business days to return in your account.

You can always contact us for any return question at [email protected].